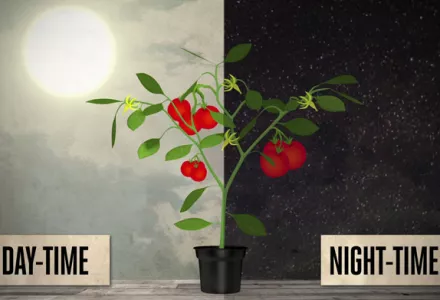

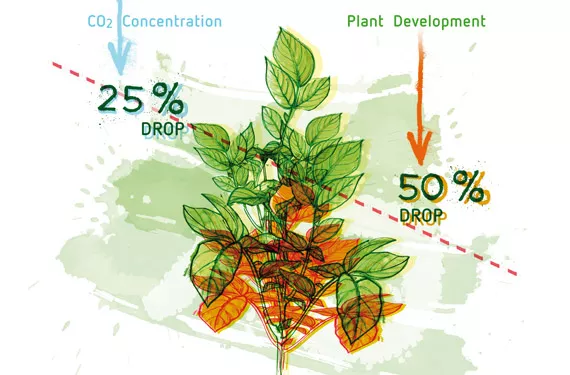

Carbon dioxide is essential to the process of photosynthesis. For growing indoor most plants require a minimum CO2 concentration of 330ppm to enable them to photo synthesize efficiently and produce energy in the form of carbohydrates. These concentrations of CO2 are enough for plants to grow and develop normally. Lower concentrations can seriously impede plant growth and general health. In fact, a drop of 25% in natural CO2 concentrations can easily inhibit growth by over 50%. Consequently, the grow room should be set up to replenish CO2 levels to at least 330ppm throughout the plant’s day time. Natural ventilation (using convection and chimney effects) or forced ventilation (using intake/ exhaust fans) can usually ensure that this objective is met adequately.

CO2 & Indoor growing

A range of factors will affect CO2 concentrations and how quickly they will fall in rooms without ventilation. These include occupancy (the surface occupied by plants), crop density/population, light intensity, horizontal air movement, light penetration of the canopy. Generally, indoor grow rooms should undergo a complete change of air every fifteen minutes, since CO2 levels can drop within minutes. During the day, increasing CO2 concentrations in the grow room to levels higher than the naturally occurring 330ppm can undoubtedly increase growth rates and yields by over 30%.

However for this to happen, all the other growing conditions also need to be optimal and favourable to proper plant metabolism. Depending on which plants are being cultivated, the benefits can take the form of higher harvest weights and/or shorter crop cycles. CO2-enriched grow rooms can also enhance crop quality. For example, edible plants may have a richer nutritional content and more pungent aroma profiles with a longer shelf life.

See also our video How does air circulation affect plant growth? and Light intensity vs. light mounting height.

Lower concentrations of CO2 can seriously impede plant growth and general health. In fact, a drop of 25% in natural CO2 concentrations can easily inhibit growth by over 50%

Factors for Indoor growing to consider when adding CO2 to ventilated growing areas

Increasing the levels of CO2 in your grow room can prove challenging. Using air changes to cool and dehumidify grow rooms can seriously hamper attempts to enrich the air with CO2. In these cases, most of the money spent on CO2 enrichment will – as it were – float straight out of the window. CO2 enrichment in such ventilated grow rooms means considering the following:

- It is usually pointless to add extra CO2 in rooms that are ventilated constantly. The plants close to the injection point will be exposed to some extra CO2, but little or no significant increase in CO2 is likely to show up on the meter and virtually all of the CO2 will end up outside, where it will also contribute to global warming.

- Even though CO2 is a heavy gas, it does not settle close to the floor in a grow room. Well-built grow rooms should have horizontal air flow (e.g. oscillating fans) and that air movement alone will be sufficient to waft any lazy CO2 molecules up into the higher air strata. It is more efficient if the CO2 generator releases the gas at the opposite side of the extraction fans in the room. The CO2 controller (sniffer) should be positioned half-way between those two pieces of equipment, usually right in the centre of the room.

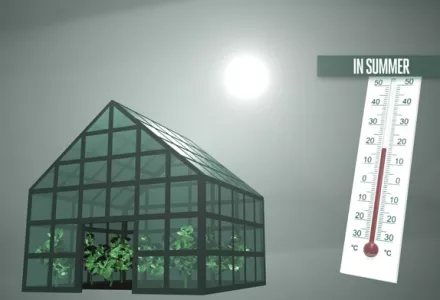

To ensure significant exposure to higher CO2 levels, the thermostatic ventilation system needs to perform well enough to actually switch off for at least 10 minutes. During that off-time a CO2 concentration of no higher than 800ppm can be easily produced. Any level higher than that is very costly. Around 50% of the 30% extra return will actually occur at a concentration of 800ppm.

The law of diminishing returns also applies to CO2 enrichment: adding another 400ppm will yield a smaller result than the first increase. Bear in mind that over the course of a day, the plant will not have had 100% exposure to higher CO2 levels and less return should be expected. It is for this reason that CO2 enrichment is rarely used in grow rooms that are ventilated. That said, it is possible to use a small air conditioner to extend the period the ventilation off-times.

Closed room environment; Indoor growing

The easiest way to get the full benefit of CO2 enrichment is in a closed grow room environment – that is, a grow room that uses air conditioning and dehumidifiers to control temperature and relative humidity levels, rather than ventilation to outside. Basically there should be no new air taken in during crop daytime. This is a more costly and energy-intensive approach, but it can guarantee higher levels of CO2 and really will enable the grower to enjoy higher crop yields.

Air conditioners

Closed & indoor room gardens are equipped with air conditioners that provide total management of the garden temperature. Extra dehumidifiers are used to control relative humidity, especially at night when no cooling is active. Throughout the day, the air conditioning performs much of the dehumidification needed in the grow room. These climate-controlled rooms can retain all of the added CO2, which reduces the cost of providing it, and the constant exposure also maximizes returns. Even so, this approach still requires some extra supervision.

Unvented gas burner

Using an unvented gas burner (propane or natural gas CO2 generator) in a closed indoor room can be difficult. These generators rely on virtually complete combustion of the natural gas, producing heat, CO2 and water vapour. A blue flame (with most of the gases used but consult your burner manufacturers guidelines) indicates complete combustion and is pretty safe. If the flame turns to red, orange and yellow, incomplete combustion is taking place and some unwanted by-products are produced such as carbon monoxide, ethylene, methane or unburned gas.

All of these by-products are produced in very small quantity but in a closed indoor room system they can build up to toxic levels for plants over the course of the day. There are many symptoms of such exposure: drooping leaves, stunted growth, necrotic dotting of the inter-venal area, yellow or orange leaf spots, dead root tips, leaf-margin burns and tip burns are a few examples.

One easy fix is to perform a small air change every hour or two. This is usually enough to lower any unwanted gas concentrations. This also replenishes oxygen levels in the room. Nonetheless regular supervision of the burner and the flame it produces is needed. An electric relay should be used to stop the production of CO2 during ventilation. Oscillating fans should not be directed at gas CO2 generator as air movement tends to interfere with the combustion process.

Daily checks should be performed to ensure a proper supply of gas to the system because if no CO2 is supplied in a closed room system, plant growth will come to a halt rapidly. Also, a CO2 monitor tends to de-calibrate over time. Physical shocks to the sniffing sensor can also skew the readings. These CO2 sensors (non-dispersive infra-red) will show higher values than the true levels if they are not properly calibrated. Contamination of sensor from fine mist foliar spraying or sulphur burning would also falsify the results and possibly damage the CO2 sensor.

Another unsuspected challenge with closed rooms is that EXTREME CLEANLINESS at all times is vital. If fungal diseases rear their ugly heads, a closed room system will mean they can spread very rapidly. The same applies to insect pests.

Environmental factors to consider

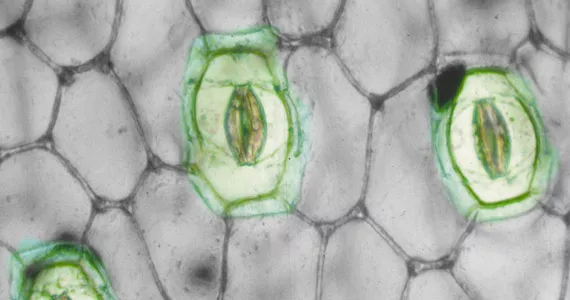

Plants generally benefit from enriched CO2 if steps are taken to maximize proper stomata functions (transpiration):

- Temperature no higher than 30°C and no lower than 18°C.

- Relative humidity (RH) between 40% (low temp) and 60% (high temp).

- Good horizontal air movement. The plants shimmer and shake lightly once every 30 seconds. An exception to this is in lower than 40% RH, where reduced air speed is better.

- The tighter the crop canopy, the more horizontal air flow is needed. Some air flow should also be directed at the lower part of the main stem.

- Light intensity is essential. The more light available, the more the plant will absorb the extra CO2 and use it for photosynthesis.

- Reduce the heat caused by light radiation (too close to canopy lighting) which tends to stress plants and reduce CO2 absorption.

- Control medium salinity (Electrical Conductivity in medium). Too high will cause nutrient burns and too low can cause deficiencies.

Is my CO2 enrichment really benefiting my plants?

The crop should develop and grow faster than usual (i.e. without extra CO2). If you do not notice any kind of added growth, you need to pinpoint the environmental factor that needs re-balancing and then tweak your equipment accordingly.